Private Label Solutions

Dove Technology specialises in providing private label solutions for the commercial flat roofing market. 99.9% of all products we supply into the market are supplied under private label to our clients.

With a wide range of formulations, we offer a one-stop solution for OEMs, system suppliers, and distributors seeking branded ancillary, adhesives and primers. If our standard formulations do not meet your performance criteria, we can reformulate them to provide a customised solution that meets your needs.

Do you need to enhance a specific aspect of your current product? We welcome you to contact us for specific development projects. We are always eager to work with you to formulate products to meet your objectives, be that in terms of performance or environmental credentials.

Our aim is to make the procurement process as simple as possible for our clients with no hidden fees or contractual obligations for the vast majority of our range. When it comes to new development projects feasibility based on production volume will be addressed early in the stages of the consultation process to ensure expectations can be set in terms of outcome early in the process.

Private Label

Solutions

Dove Technology specialises in providing private label solutions for the commercial flat roofing market. 99.9% of all products we supply into the market are supplied under private label to our clients.

With a wide range of formulations, we offer a one-stop solution for OEMs, system suppliers, and distributors seeking branded ancillary, adhesives and primers. If our standard formulations do not meet your performance criteria, we can reformulate them to provide a customised solution that meets your needs.

Do you need to enhance a specific aspect of your current product? We welcome you to contact us for specific development projects. We are always eager to work with you to formulate products to meet your objectives, be that in terms of performance or environmental credentials.

Our aim is to make the procurement process as simple as possible for our clients with no hidden fees or contractual obligations for the vast majority of our range. When it comes to new development projects feasibility based on production volume will be addressed early in the stages of the consultation process to ensure expectations can be set in terms of outcome early in the process.

Development project process

While working on bespoke product development projects, we can customise the process to align with your schedule and internal procedures. However, the following outline provides a general idea of the typical process.

1. Technical Consultation

We will schedule a meeting with our technical team to discuss the aims, objectives, and requirements of the development. During this meeting, we will determine the specification parameters and testing protocols needed to quantify performance. Depending on the project, we may be able to estimate the timeline for development at this stage. However, in certain cases, initial development work may be necessary to determine the duration of the process.

2. Development

After determining all the objectives and aims, our team will commence the development process. To ensure that your expectations regarding timelines are met, we will maintain communication with your technical team and provide regular updates on the various stages involved. During the process, we will require samples of your materials and any particular substrates to conduct testing throughout the development.

3. Product Testing

Once a formulation has been confirmed, the final phase of internal testing will involve evaluating the performance of the product on relevant substrates and materials. Previous work conducted during the development process will be analysed and compiled into a final report for evaluation. Lager scale trials will then be carried out to ensure that the project’s requirements have been met in terms of suitability for an application. This phase will typically encompass to scale-up from lab-based samples to larger batch production.

4. Independent Testing

The necessity for independent testing can vary depending on the product and its intended use. This is why comprehensive internal testing procedures should be implemented during the development process. It’s important to have complete confidence that the product will meet all requirements and perform effectively, so that it can pass any independent testing with ease. This will help to minimise associated costs and avoid any delays in launching the product to market.

Regulatory Considerations

Regulations governing chemical products can differ depending on where you’re located. Our expertise can assist and advise you in fulfilling your regulatory obligations and ensuring compliance when launching a new product.

UFI Registration

Within the European Union, chemical products are mandated to possess a unique UFI Code, which serves as a formulation identification number. This code includes all constituents, both hazardous and non-hazardous, to provide responders with critical information in case of an emergency involving the product. Our products have UFI registration in most European countries, facilitating a streamlined registration process through the unification of UFI codes. In the event of new product development, we can provide guidance on obtaining UFI registration and meeting other regulatory requirements.

SDS Generation

We can produce Safety Data Sheets (SDS) for the products you wish to procure, tailored to the specific distribution location and language requirements. Our SDS are frequently revised to comply with evolving regulations, and we provide our clients with up-to-date information on any changes to product classifications.

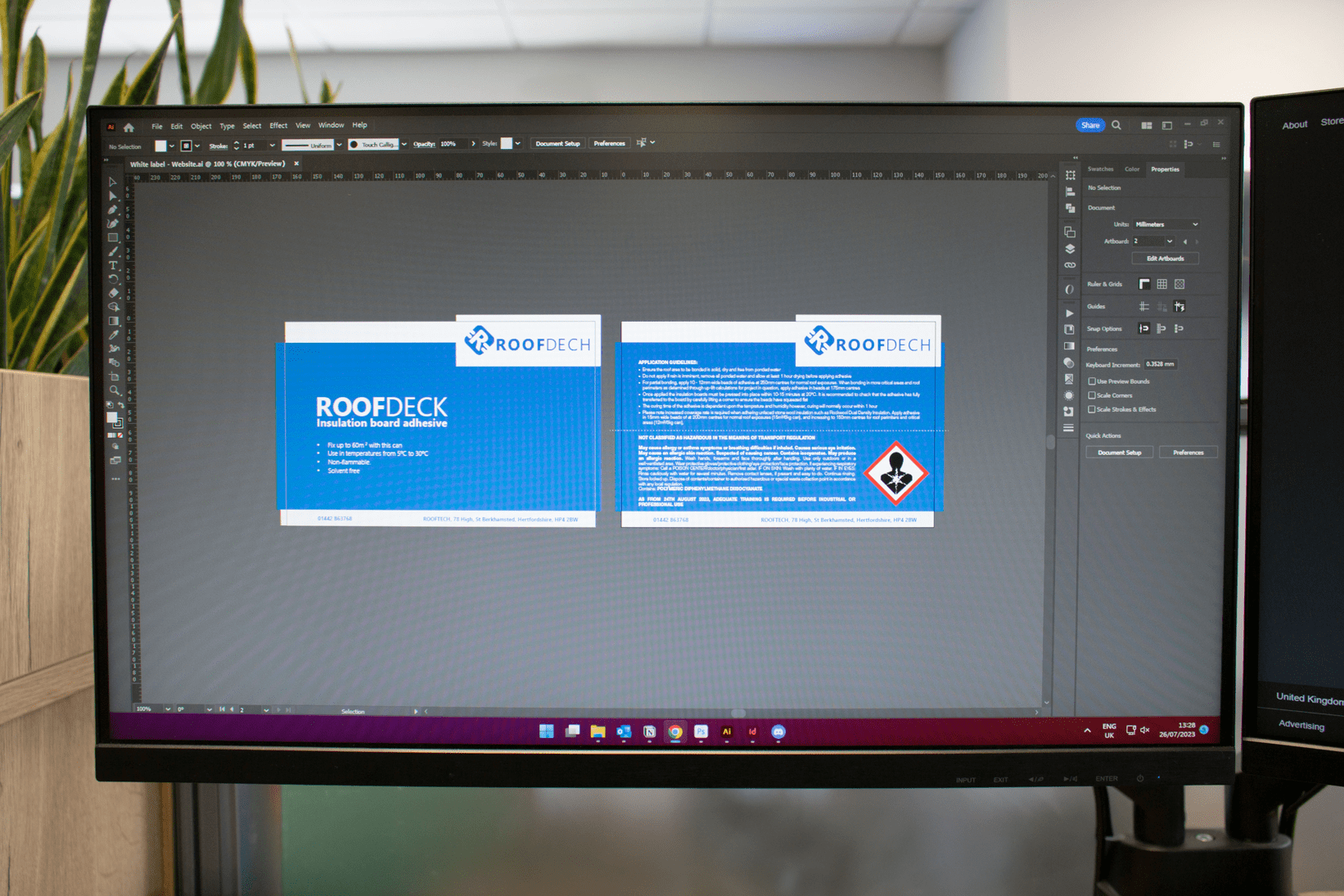

Labelling

We will identify the necessary information for your product labels to meet CLP/GHS regulatory guidelines and then collaborate with our internal design team, or your own, to incorporate your branding requirements. Labeling requirements differ depending on the destination countries and packaging sizes of the product. However, we remain available to ensure your compliance throughout the process.

Branding & Marketing

The concluding stage of the process concentrates on branding and literature, amalgamating all technical information and guidelines, and preparing the product for launch.

01. Labelling & Printed Packaging

At this stage, the regulatory compliance aspect of the product labeling requirements has been defined. We can now advise you on options such as printed packaging or labeling, and subsequently provide these elements to your branding and marketing teams for label design, or collaborate with our design team to produce artwork that adheres to your brand guidelines.

02. Documentation

Our designers will incorporate technical information from our technical department, such as application guidelines and technical specifications, which are tailored to your applicable substrates and application processes. We will then work with you to design these materials in line with brand guidelines or be on hand to assist with validation of any literature you wish to generate yourselves to ensure the technical information is accurate.

03. Video & Photography

Once all the final details have been ironed out our team can also assist with putting together branded product training and demonstration videos and product photography for your own marketing purposes. Giving you the full package from inception to product launch.