Technical Department

We want you to be fully informed before you commit to a product, so we do the testing for you – whether this is on-site or at our research and development facilities – this will show you the suitability and performance of the product and give you the facts and figures so you can make an informed decision.

Having a strong research and development team allows us to adapt our products, meet our client’s requirements, and give optimum results every time. We also have the means to develop a bespoke solution to ensure that it is the perfect match for your materials.

Technical Department

Dove Technology has a wealth of knowledge when formulating for the commercial roofing market, and our team are on hand to quantify the performance of our products in conjunction with your membranes and specifications. We want you to be fully informed before you commit to a product, so we do the testing for you– this will show you the suitability and performance of the product and give you the facts and figures so you can make an informed decision.

Having a strong research and development team allows us to adapt our products, meet our client’s requirements, and give optimum results every time. We also have the means to develop a bespoke solutions to ensure that maximum compatibility is achieved every time.

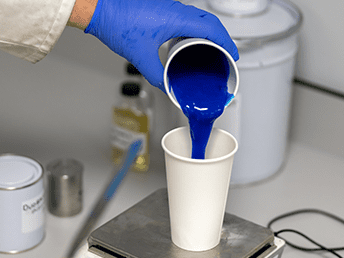

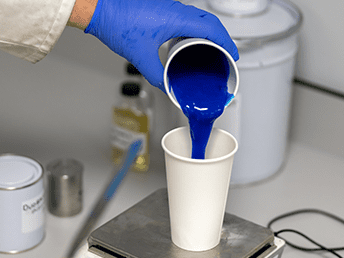

Product Development

We have been formulating and developing adhesives specifically for the flat roofing market for the last 15 years. We have a core range of adhesives and primers for almost every application within the industry.

From our core products we also have a multitude of formulation variations which can be adapted to suit the requirements of our clients, should that be due to the climate in which they are being applied or meeting VOC regulations. This ability allows us to ensure we can obtain optimal product performance for the specific membrane or system build-up.

Product Testing

To ensure our products give the best results every time, we perform rigorous in-house testing on each of our products against a wide range of roofing materials. Once we’ve identified the most suitable product for your application we can test your systems to ensure the product meets expectations.

We will work with you to determine the best test methods and then return to you with an informative and in-depth report providing all the information you require. This allows you to make an informed decision based on facts and figures to determine the best product to bond the roofing system in question.

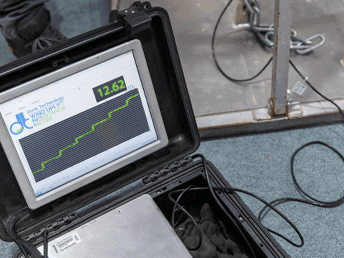

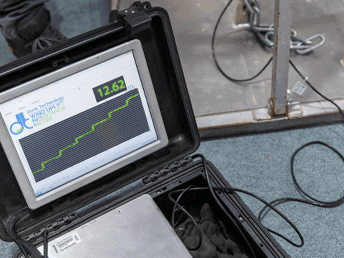

On-site Testing

From time to time unusual substrates and materials can rear their heads and investigation is required to ensure the success and longevity of your new roofing system.

This is why our team are on hand to perform on-site testing providing accurate and recordable results to give your clients certainty and peace of mind using our purpose-built tensometer. Allowing you to provide your client with an in-depth report, categorically demonstrating the strength of the system in question and dispelling any doubts about product performance.

Product Development

We have been formulating and developing adhesives specifically for the flat roofing market for the last 15 years. We have a core range of adhesives and primers for almost every application within the industry.

From our core products we also have a multitude of formulation variations which can be adapted to suit the requirements of our clients, should that be due to the climate in which they are being applied or meeting VOC regulations. This ability allows us to ensure we can obtain optimal product performance for the specific membrane or system build-up.

Product Testing

To ensure our products give the best results every time, we perform rigorous in-house testing on each of our products against a wide range of roofing materials. Once we’ve identified the most suitable product for your application we can test your systems to ensure the product meets expectations.

We will work with you to determine the best test methods and then return to you with an informative and in-depth report providing all the information you require. This allows you to make an informed decision based on facts and figures to determine the best product to bond the roofing system in question.

On-site Testing

From time to time unusual substrates and materials can rear their heads and investigation is required to ensure the success and longevity of your new roofing system.

This is why our team are on hand to perform on-site testing providing accurate and recordable results to give your clients certainty and peace of mind using our purpose-built tensometer. Allowing you to provide your client with an in-depth report, categorically demonstrating the strength of the system in question and dispelling any doubts about product performance.

Our Expertise

Our research and development team will work with you, hand in hand, to develop a bespoke solution to meet your requirements.

We have a wealth of knowledge within our team with a core focus on Polyurethane product development and manufacture, from prepolymer to finished solution. Other key manufacturing areas are in acrylic and solvent borne rubber based polymers.

01. Polymer Formulation

Once the aims of your development have been reviewed we will work to formulate a base solution meeting your key requirements.

02. Compatibility & Performance Testing

Once formulation options have been developed we will test the solution to agreed test methods such as BS EN or ASTM standards. We will work with you to agree a test regime that meets the project profile. This allows you to have confidence of the products performance before proceeding with independent testing.

03. Independent Testing

Once we’ve met product performance aims and practical application trials have been conducted, you can then move forward into independent testing knowing our adhesives and primers will outperform within the roofs build-up.

Our Expertise

Our research and development team will work with you, hand in hand, to develop a bespoke solution to meet your requirements. We have a wealth knowledge within our team with core focus on Polyurethane product development and manufacture, from prepolymer to finished solution. Other key manufacturing areas are in acrylic and solvent borne rubber based polymers.

01. Polymer Formulation

Once the aims of your development have been reviewed we will work to formulate a base solution meeting your key requirements.

02. Compatibility & Performance Testing

Once formulation options have been developed we will test the solution to agreed test methods such as BS EN or ASTM standards. We will work with you to agree a test regime that meets the project profile. This allows you to have confidence of the products performance before proceeding with independent testing.

03. Independent Testing

Once we’ve met product performance aims and practical application trials have been conducted, you can then move forward into independent testing knowing our adhesives and primers will outperform within the roofs build-up.