Spraybond® Canister Setup Guide

How to Setup a

Spraybond® Canister

Please find our simple Spraybond Canister Adhesive and Primer set-up guide below, showing how to safely assemble your hose and spray gun ready for application. Or alternatively, you can watch the instructional video.

If you run into any trouble you can always contact our technical team who can troubleshoot any issues you may be experiencing and ensure you are up and running without a hitch.

You can email [email protected] or call

+44 (0) 1785 818258 for further assistance.

Setting Up

Spraybond® Canisters

Please find our simple Spraybond Canister Adhesive and Primer set-up guide below, showing how to safely assemble your hose and spray gun ready for application. Or alternatively, you can watch the instructional video.

If you run into any trouble you can always contact our technical team who can troubleshoot any issues you may be experiencing and ensure you are up and running without a hitch.

You can email [email protected] or call

+44 (0) 1785 818258 for further assistance.

Step one:

Ensure the canister has been stored suitably, canisters should be stored between 15°C – 30°C prior to use. This ensures the product will apply at a suitable pressure for optimal performance.

Make sure you are wearing appropriate PPE such as gloves, eye protection – consult products safety data sheet for further details for the specific product.

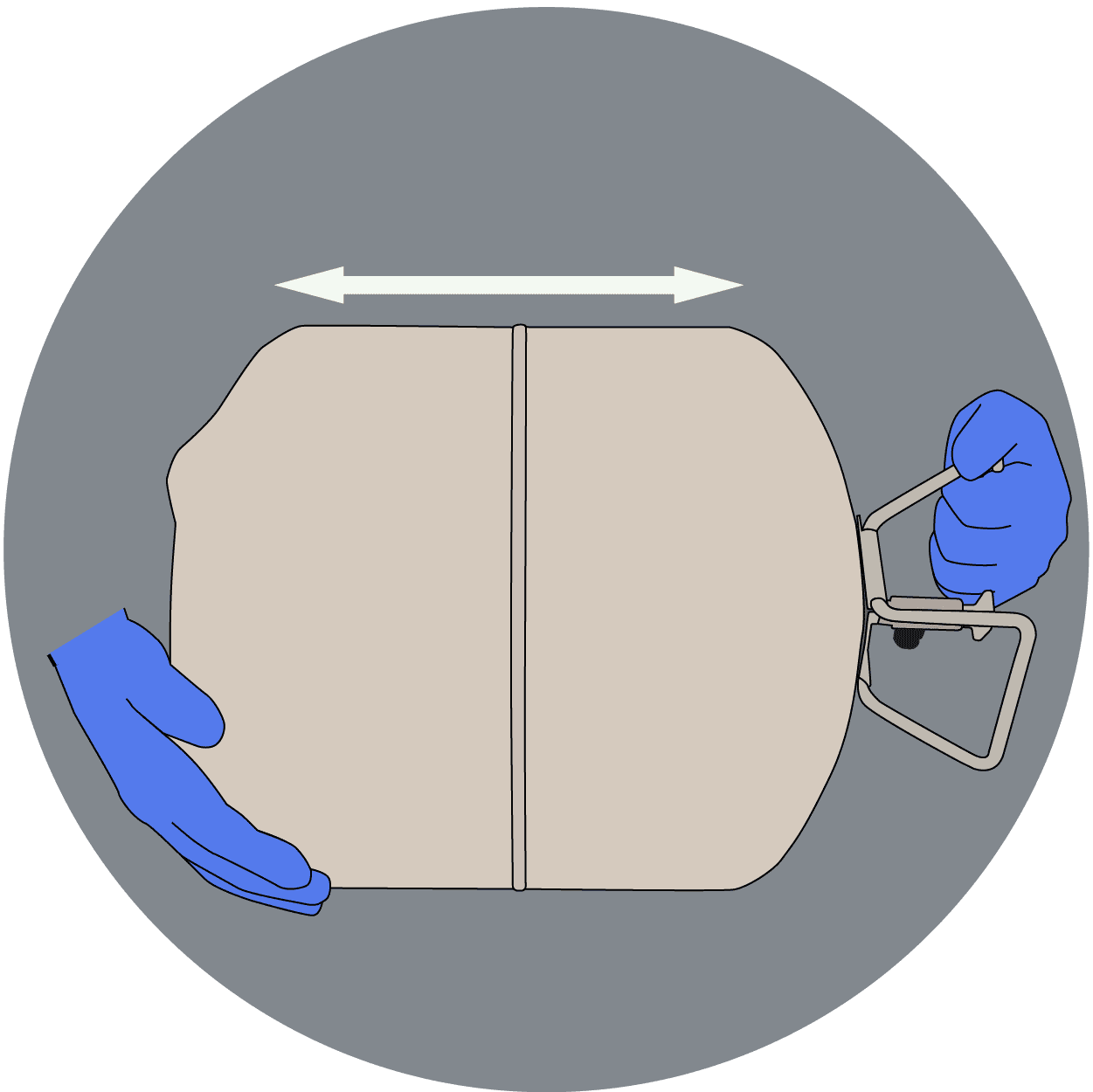

Shake the canister thoroughly, left to right, for 30 seconds; as pictured on the right.

Step Two:

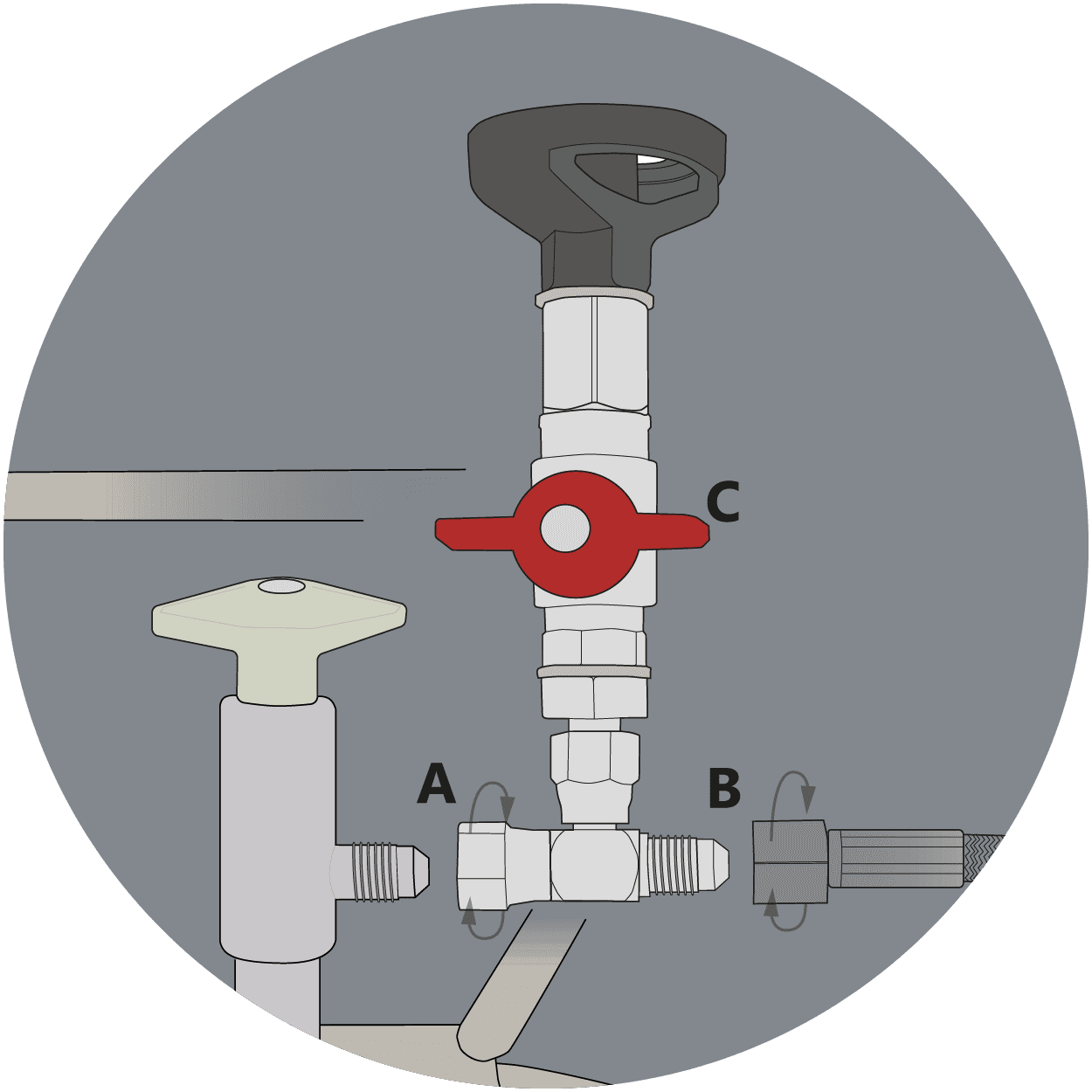

The next stage is to connect up the cleaning adaptor and the hose to the canister. We recommend the use of cleaning adaptors as it allows you to fully clean out the hose and gun when required. That way, your hose and gun will never get clogged when you come to disconnect.

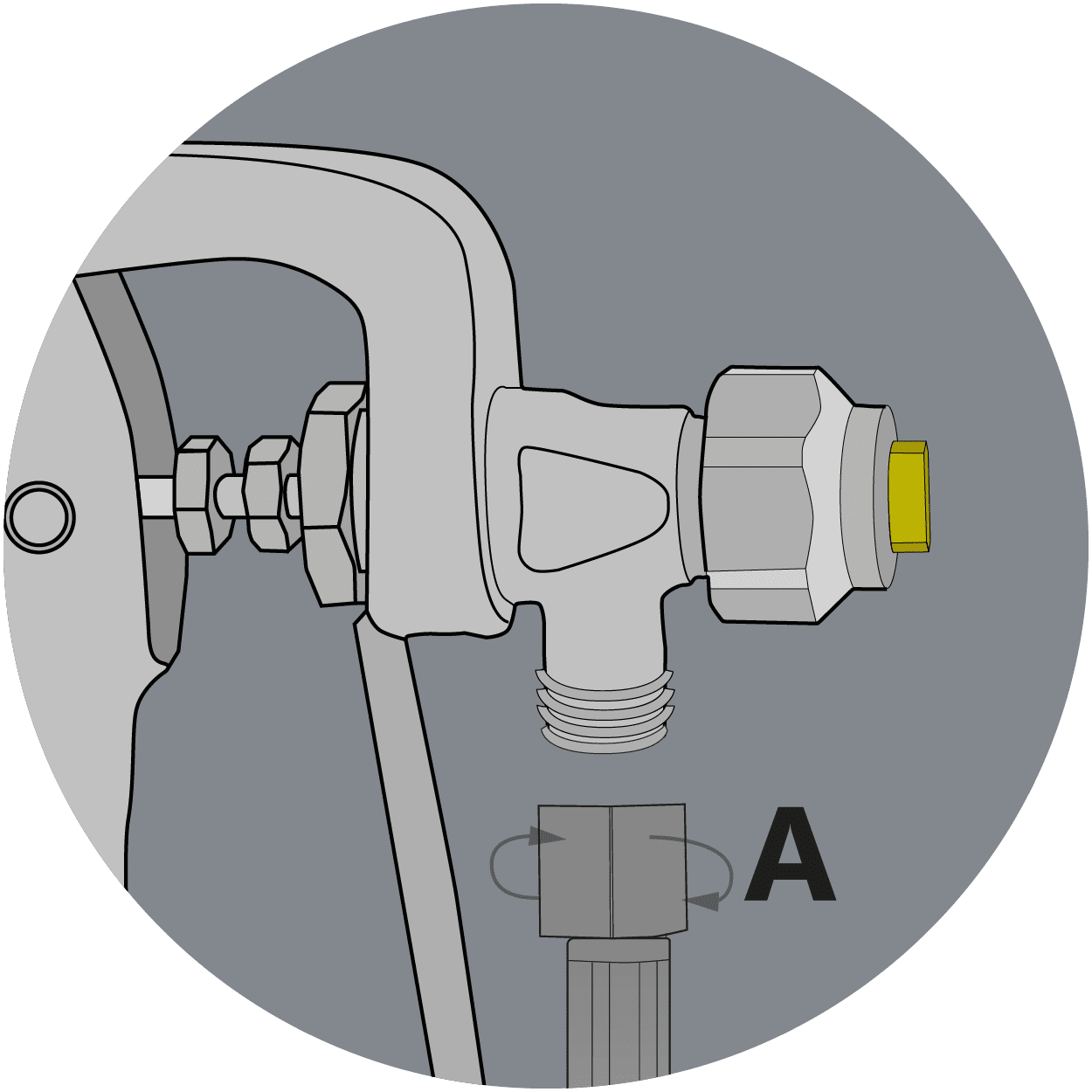

Firstly, connect the cleaning adapter to the canister valve (A), tighten until secure with a spanner, take care not to overtighten.

Connect the hose to the cleaning adaptor (B), tighten until secure with a spanner, take care not to overtighten.

If you are not using a cleaning adaptor, connect your hose directly to the canister valve (A), tighten until secure with a spanner, take care not to overtighten.

Once you are all connected, make sure that the cleaning adaptor valve (C) is in the closed / horizontal position as shown on the picture in this section.

Step three:

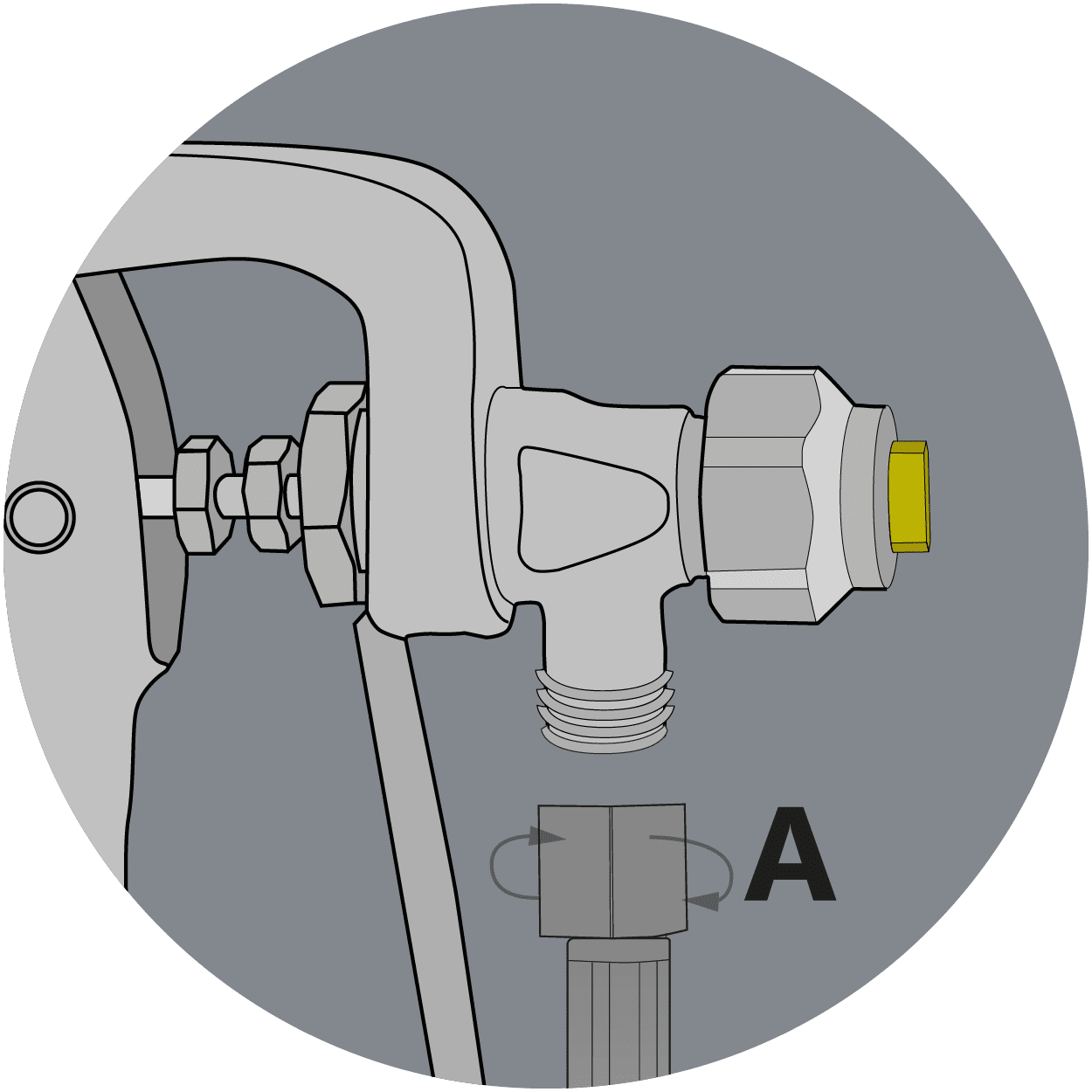

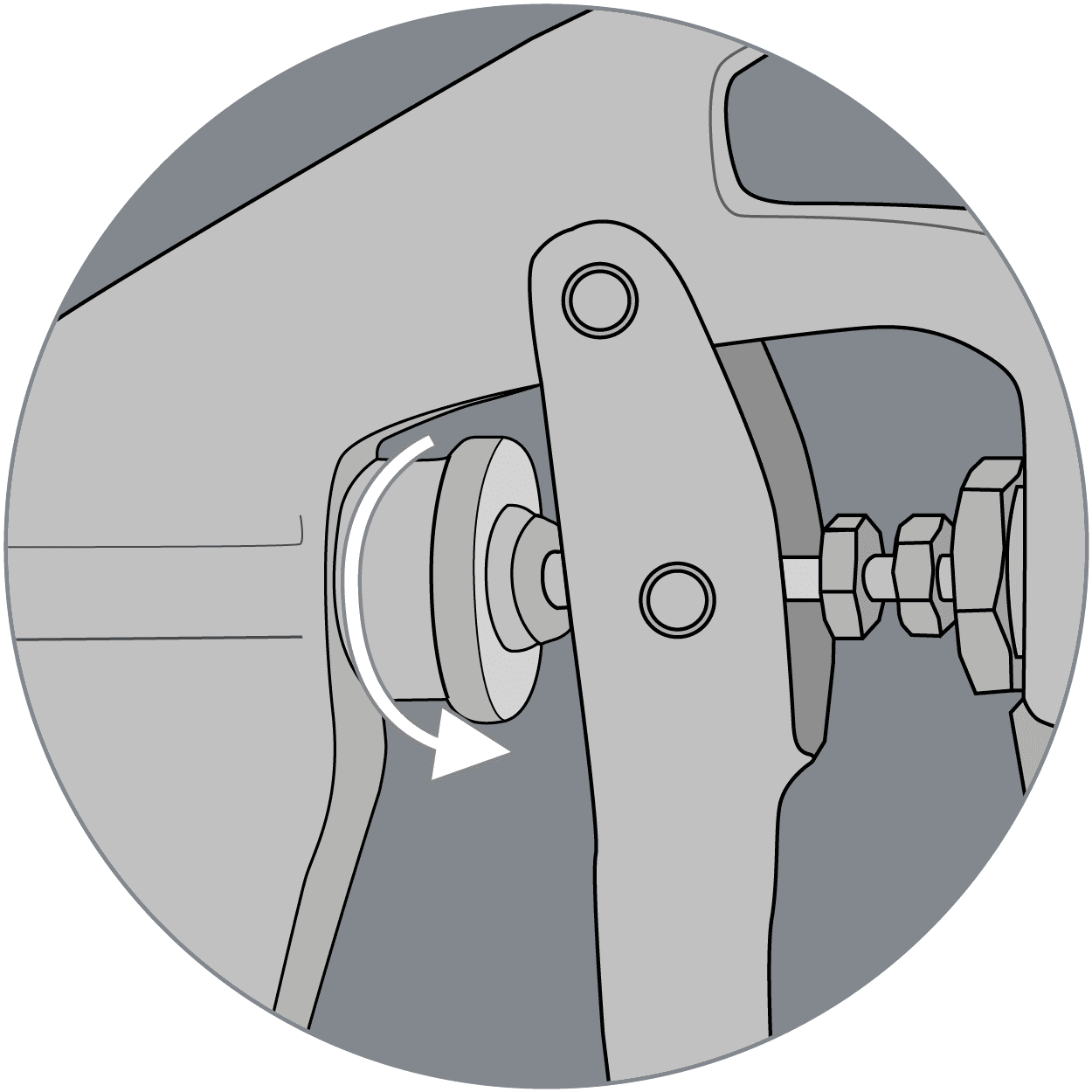

Connect the hose directly to the gun (A), tighten until secure with a spanner, take care not to overtighten.

At this stage it’s always best to check the spray tip is clean and positioned in a suitable position.

Spray tips are available in a range of sizes, for our product range we typically recommend either 9501 or 8002. All of our spray guns come with tips as standard, with replacements available.

Step three:

Connect the hose directly to the gun (A), tighten until secure with a spanner, take care not to overtighten.

At this stage it’s always best to check the spray tip is clean and positioned in a suitable position.

Spray tips are available in a range of sizes, for our product range we typically recommend either 9501 or 8002. All of our spray guns come with tips as standard, with replacements available.

Step four:

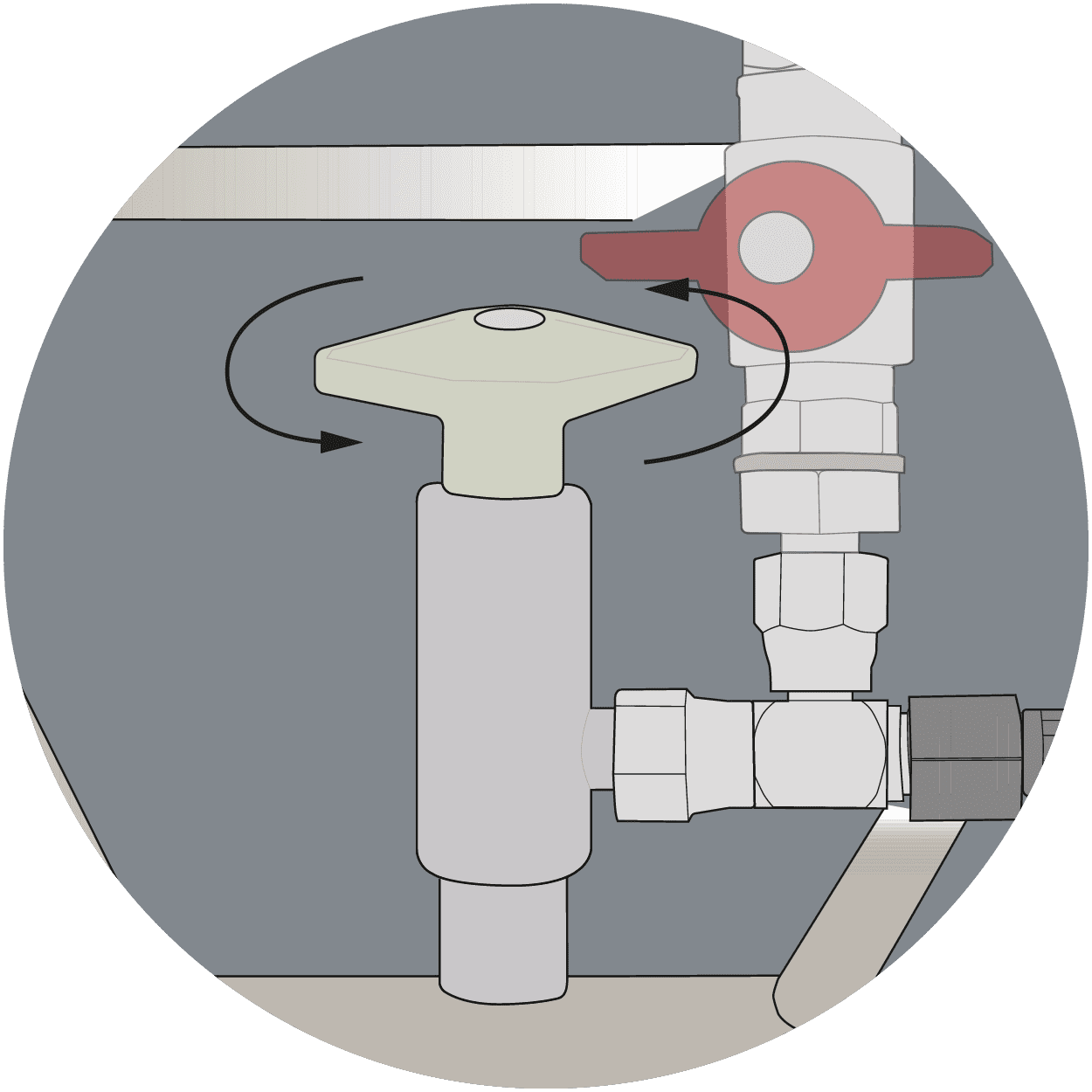

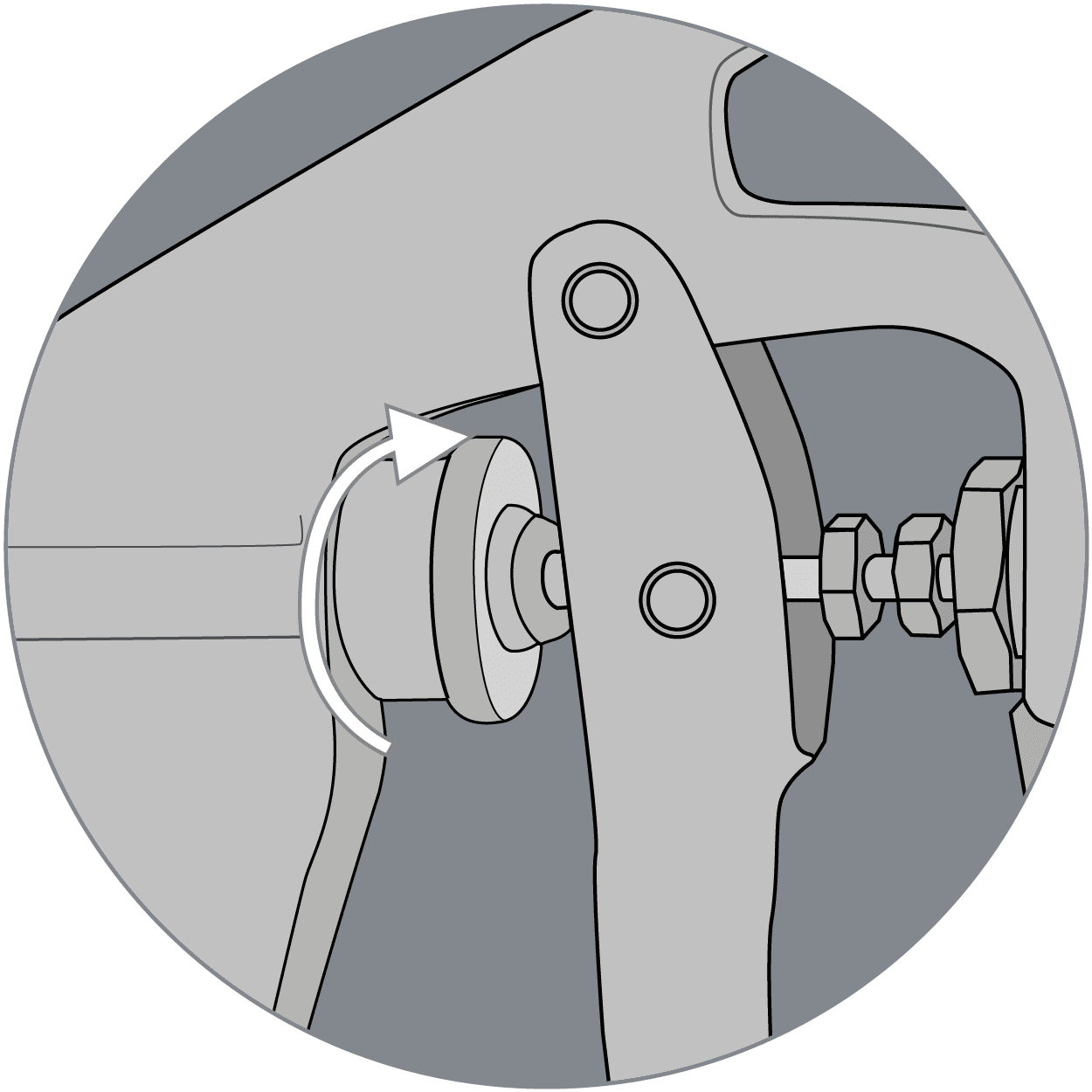

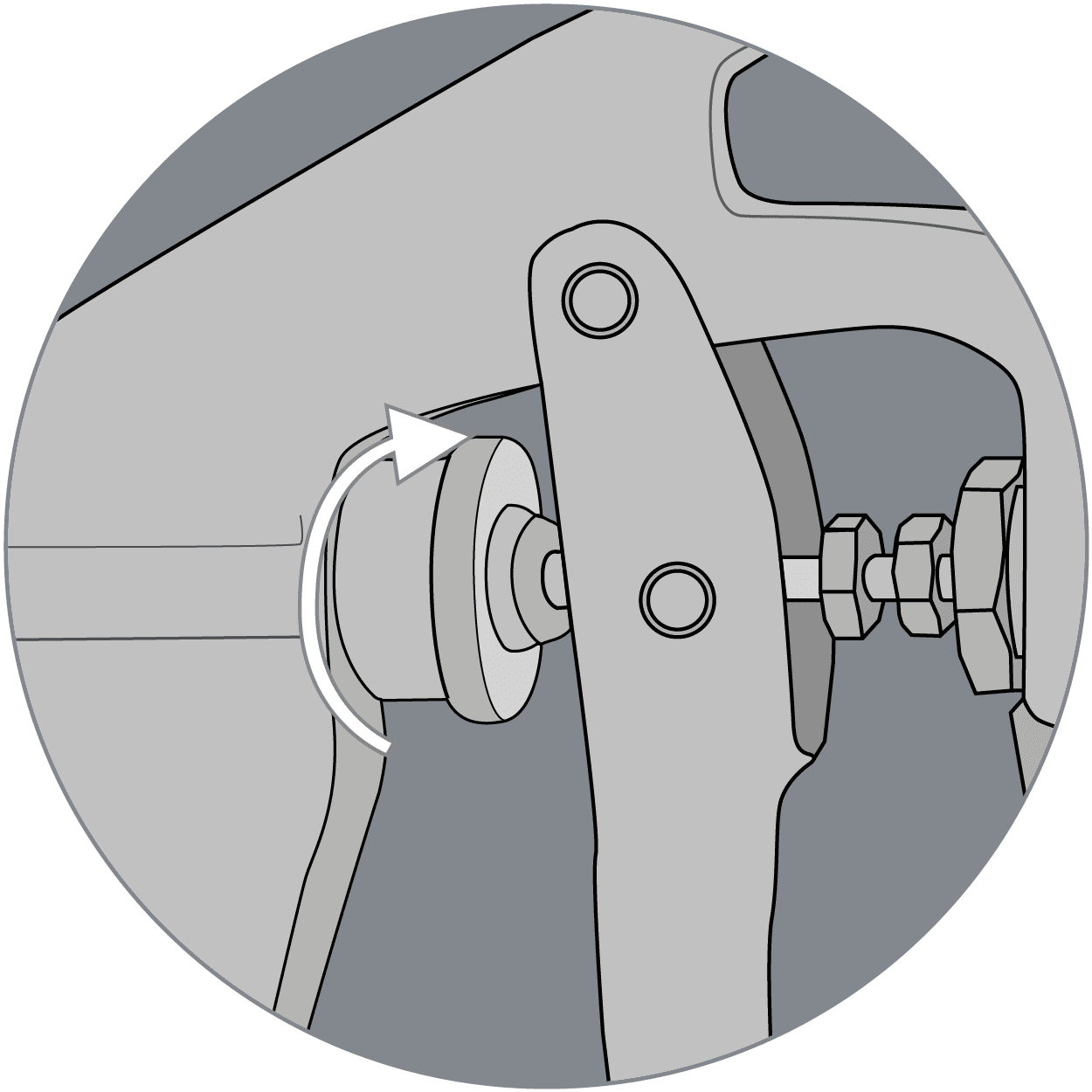

Once you’re ready for work to commence open the canister valve turning it clockwise by hand.

When the valve is fully open check all connection points to ensure there are no signs of leakage. If any are leaking ensure that the connections are suitably tightened.

Step five:

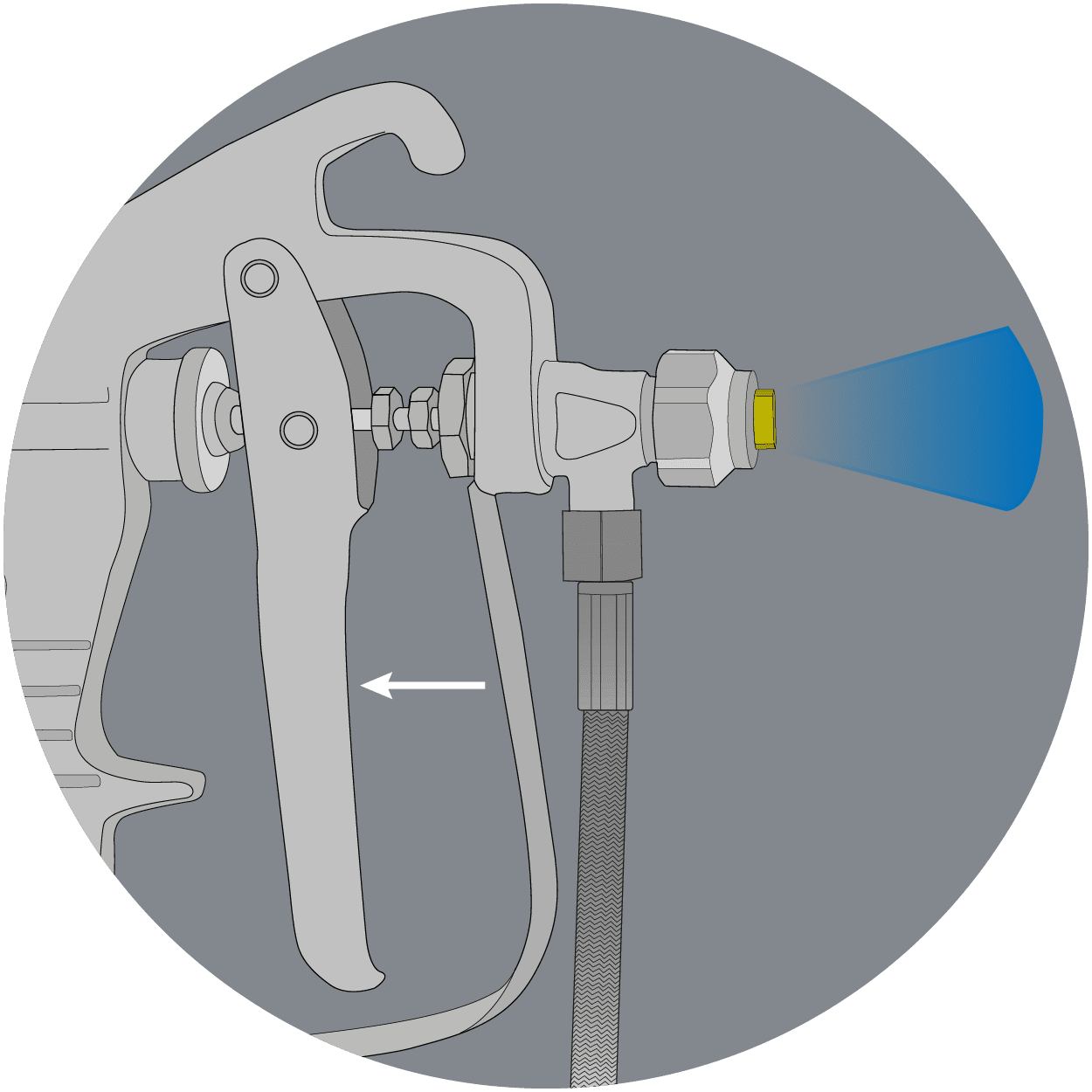

When you’re ready to apply the product, turn the control knob, behind the guns trigger, clockwise. Always ensure you are in a suitable well ventilated area when you come to use your canister adhesive or primer.

The spray pattern can be adjusted in size using the control knob, becoming wider the further open (clockwise) you turn it.

The turn the gun off you turn the control knob fully counter-clockwise.

Step Six:

We would recommend doing a spray test on a piece of scrap material to ensure you are getting your required spray size / pattern. Pull the guns trigger to spray the adhesive or primer.

Consult the individual products technical data sheet for application guidelines and coverage rates.

Step Seven:

When you have finished applying product, turn the gun off by fully turning the control knob counter clockwise so the trigger can no longer be pulled. Always turn off the gun at the control knob when you stop working to prevent blockages. Never turn off at the canister unless you are cleaning through using a cleaning adaptor.

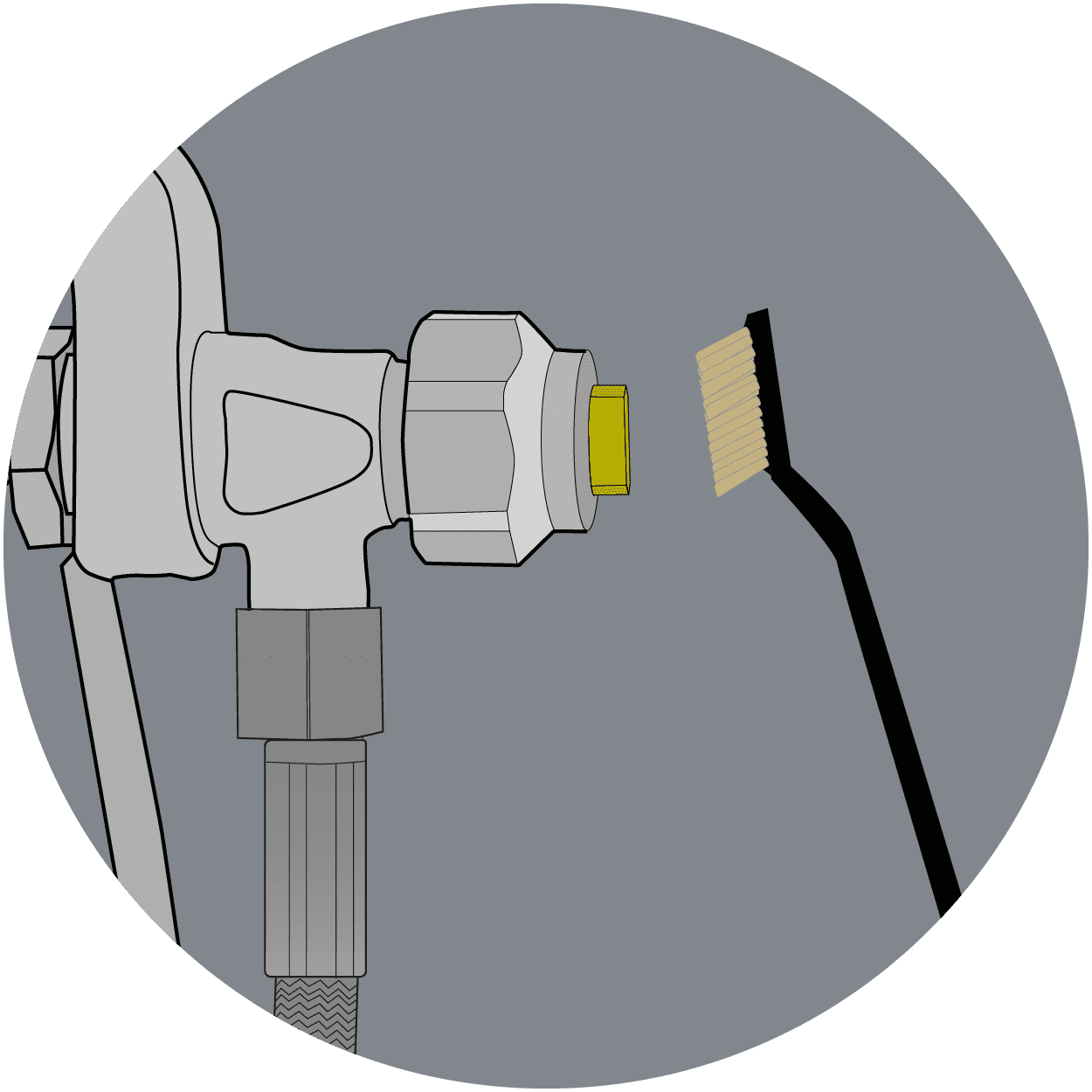

Once turned off clean the spray tip of the gun with Spraybond Cleaning Solvent and a wire brush until no adhesive or primer residue remains.

Step Seven:

When you have finished applying product, turn the gun off by fully turning the control knob counter clockwise so the trigger can no longer be pulled. Always turn off the gun at the control knob when you stop working to prevent blockages. Never turn off at the canister unless you are cleaning through using a cleaning adaptor.

Once turned off clean the spray tip of the gun with Spraybond Cleaning Solvent and a wire brush until no adhesive or primer residue remains.

Step Eight:

Once turned off, clean the spray tip of the gun with Spraybond Cleaning Solvent and a wire brush until no adhesive or primer residue remains. Save yourself the downtime when you turn up tomorrow and find a blocked gun, and give it a clean.

Step Nine:

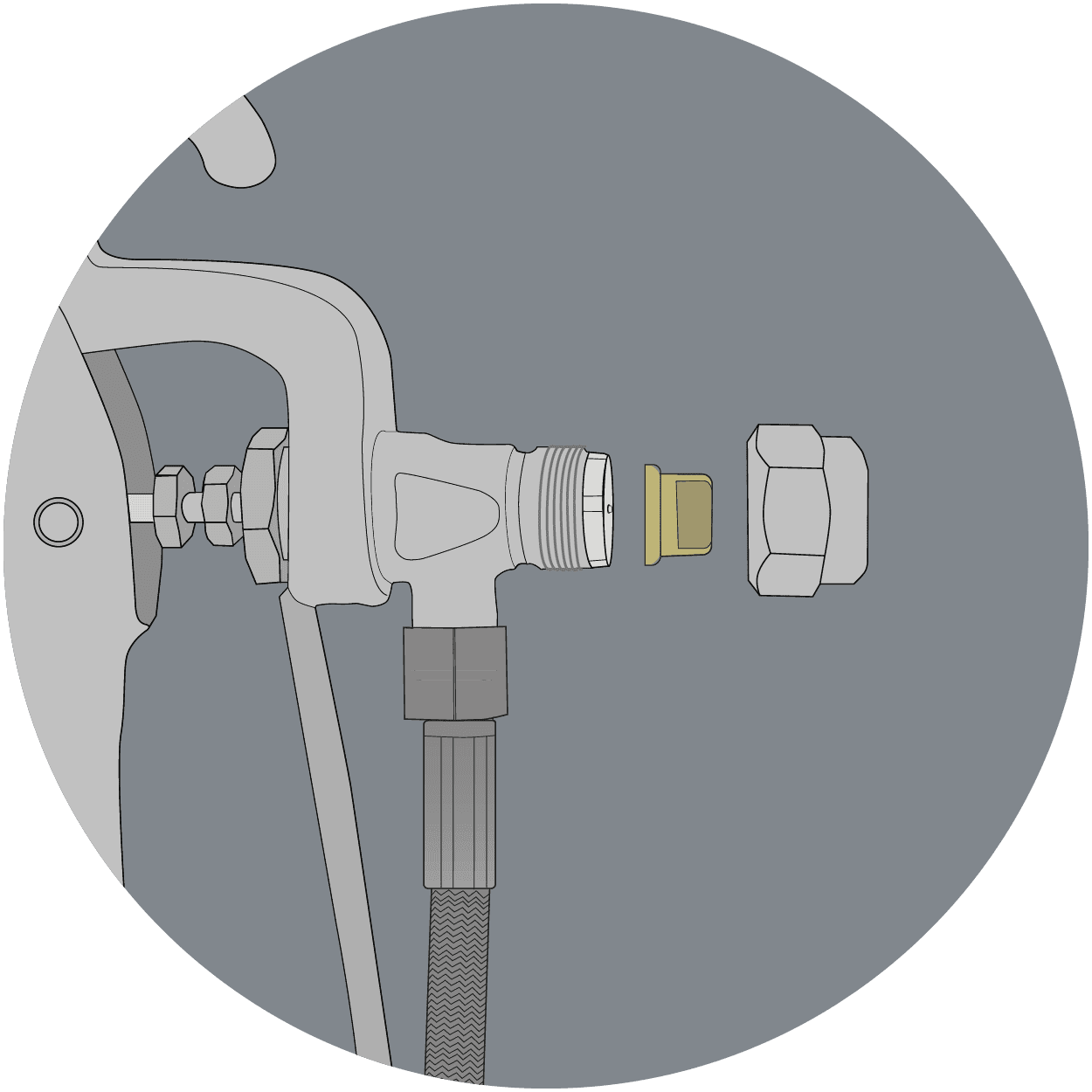

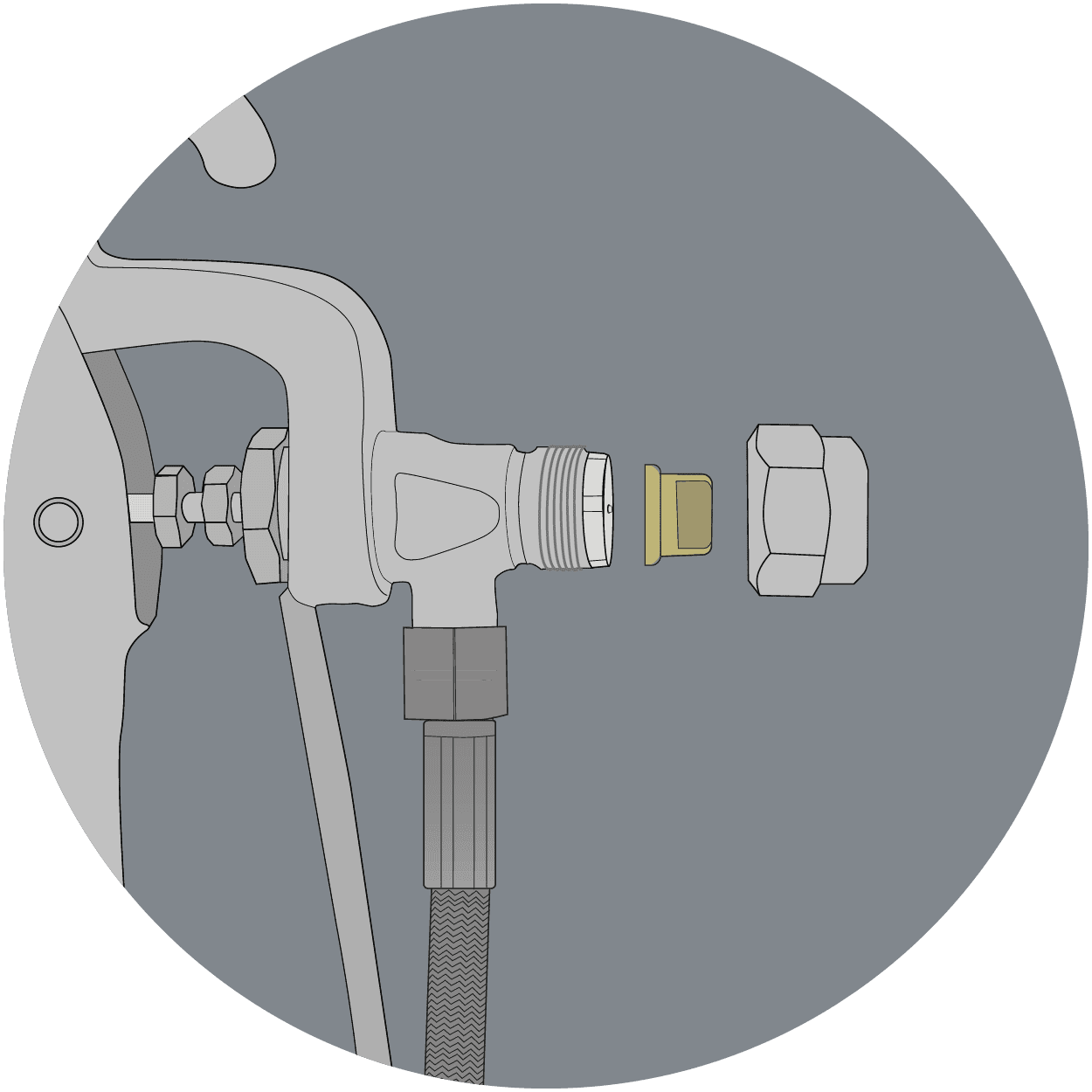

If your spray gun has been put through its paces, we would recommend removing the front nut which secures the brass spray tip. Please note that a removable spray tip is only present on DT-STD & DT-SG spray guns.

Once removed the brass spray tip could be soaked in an appropriate tin with solvent and left to soak. The tip can then be removed and cleaned thoroughly with a wire brush. Always check the back of the spray tip to see whether any residue remains.

Step Nine:

If your spray gun has been put through its paces, we would recommend removing the front nut which secures the brass spray tip. Please note that a removable spray tip is only present on DT-STD & DT-SG spray guns.

Once removed the brass spray tip could be soaked in an appropriate tin with solvent and left to soak. The tip can then be removed and cleaned thoroughly with a wire brush. Always check the back of the spray tip to see whether any residue remains.